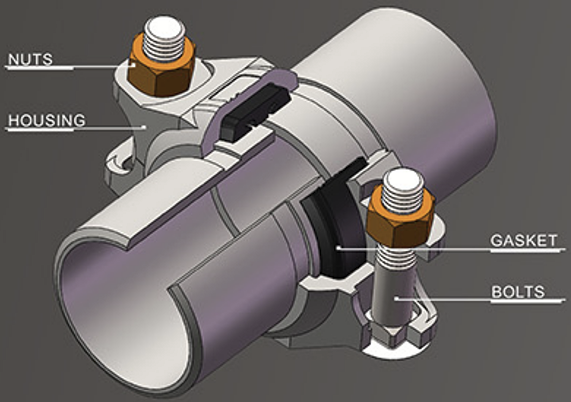

Knappe Composites provides high-quality stainless steel flexible couplings specifically engineered for water treatment piping systems to ASTM standards. These couplings are compatible with cut grooved pipes in various diameters, including 1.5 inch, 2 inch, 3 inch, and 4 inch, and are designed and tested to withstand pressures up to 1200 PSI.

Materials:

Housing: Made from 316 stainless steel or duplex material, delivering exceptional load resistance and superior corrosion protection in aggressive environments.

Bolts: Made from 316 stainless steel, offering high load resistance and robust protection against corrosion in harsh atmospheric conditions.

Nuts: Made from silicon bronze to prevent seizing and resist corrosion.

Gasket: EPDM, perfectly suited for contact with water and a wide range of chemical media.

NSF 61 drinking water certified gaskets, as well as material and quality certificates, different sizes or material are available upon request.

Achieve seamless alignment and enhanced flexibility with these innovative flexible couplings. Designed for full rotation before tightening, they easily accommodate thermal expansion, misalignment, and seismic stress. Plus, the self-restrained joints securely hold pipes against full pressure thrust loads without extra restraints.

Knappe Composites provides high-quality stainless steel weld neck and slip on flanges with stub ends for water treatment piping systems to ASTM / ASME B16.5 and EN 1092-1 standards in various diameters, including from 3 inch to 12 inch an in different pressure ratings.

Materials:

Material and quality certificates, different sizes or material are available upon request.

Knappe Composites manufactures high-quality stainless steel bends and straight pipe extensions using orbital and robotic fiber laser welding with automatic filler wire feeding. These components are specially designed for X-type membrane housing and water treatment systems.

The advantages of laser welding are, for example, less heat distortion due to lower heat input, more precise weld seams, better welding depth ratio for the best internal weld seams.

The stainless steel bends and straight extensions are peened with stainless steel beads to reduce the surface roughness, increase the surface hardness and corrosion resistance of the stainless steel and achieve an aesthetic appearance.

On request, the stainless steel bends and straight extensions can also be electropolished to achieve maximum corrosion resistance, a shiny and decorative appearance, a passive oxide layer and hygienically clean internal and external stainless steel surfaces.

On request, the weld seams can be x-rayed for quality assurance.

Available materials:

316

Duplex

Super duplex

Material and quality certificates as well as different sizes or materials are available on request.

© 2024 Knappe Composites SAS ; Knappe Composites – X-Type RO Membrane Housings. | Webdesign by ComUnique.fr