The Company started with the development of inlined membrane housings for 2.5, 4, 4.6 and 8 inch spiral wound membranes. The unique in liner invented by Knappe prevents medium contact with the fiberglass shell.

That results in many advantages:

Knappe Kunststofftechnik GmbH, founded by Mr. Holger Knappe in Germany, pioneered the development of inlined membrane housings for desalination industries with support from the German Ministry of Research. With innovative technology and expertise in fiber composite materials, Knappe set new standards in membrane housing production. Specializing in membrane housings for water filtration, Knappe utilizes advanced production centers and engineering tools for optimal design and performance. As a co-founder of Spiral in Santee, Knappe’s fiberglass inlined membrane housings, known as AnyChem™, have gained international recognition for their reliability, longevity, and compatibility with various mediums. Trusted for over 40 years, these housings have been integral in addressing global water scarcity challenges across diverse sectors including municipal water desalination, agriculture, wastewater treatment, and industrial processes.

Knappe Kunststofftechnik GmbH started to build assembled prefabricated skids in high quality alloy stainless steel with headers and bends. Standardization was the goal when Knappe created a new way of combining various numbers of FRP membrane housings in a unit.

Connections between membrane housings and collectors were designed to be assembledstress free allowing also thermal expansion of the system. Collector and pipe welding are made by computer controlled welding.

Knappe Kunststofftechnik GmbH supplied SKIDS, housings and collectors for mid-size projects for many different industries including municipal jobs and power stations.

Knappe Kunststofftechnik GmbH started realizing large projects.

Knappe Kunststofftechnik GmbH became an investing company and stopped the production in Germany.

Knappe Composites SAS built a new factory in southern France and invested in a new production facility.

In 2004, Knappe Composites SAS started production and continued the production and sales of AnyChem™ inlined FRP membrane housings and AnyRack™ skids.

Knappe Composites SAS started to invest in injection molding machines and the necessary equipment.

The new self sealing endplate assemblies for 8inch housings were created and produced by computer numerical controlled turning and milling centers assuring high quality manufacturing with high quality materials resulting in optimum cost-effective membrane housing production.

International Patents were granted.

Knappe develops and produce all components in-house which guarantees high quality, short delivery time and flexibility in serving their customers.

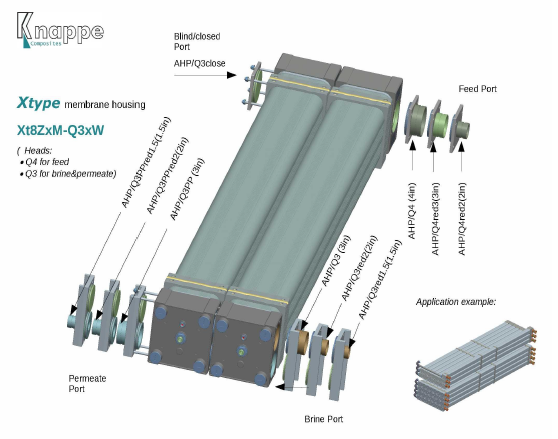

Knappe initiated the Xtype project to develop a cutting-edge FRP inlined modular membrane housing system for 8-inch standard membranes, securing international patents for its innovative design.

The development aimed to enhance key features of previous housings while significantly reducing costs and footprint.

The Xtype system offers numerous benefits, including enhanced chemical resistance, compliance with regulatory standards, and simplified construction of reverse osmosis systems. With a modular design and reduced reliance on high-alloy connectors, the Xtype system provides cost-effective solutions for water treatment applications worldwide.

Knappe developed for a Norwegian company composite tanks with 1,2m diameter to hold 3000 flat membranes to generate osmotic power with a max. operating pressure of 16bar.

Knappe also developed and built the injection mold for flat membrane frames with a diameter of 1,2m.

Forward osmosis is used to generate renewable and emissions-free energy contributing to ecofriendly power production.

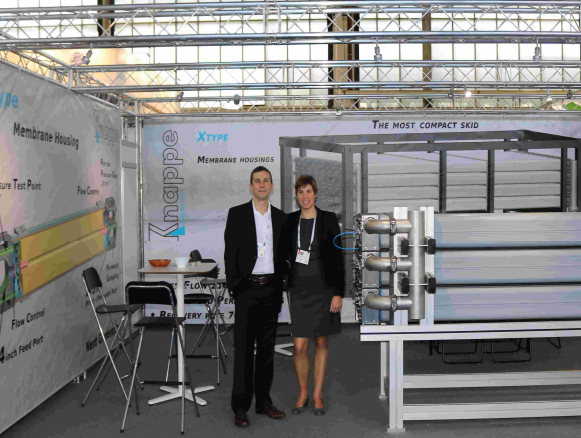

Knappe attended Aquatech 2015 in Amsterdam and presented

for the first time the new 8 inch Xtype membrane housings to the

public. Xtype membrane housings received an innovation prize in its

category.

Knappe SAS supplied the first Xtype membrane housing for municipal drinking water projects in Europe.

Knappe SAS realized for example projects like Sandweier in Germany and Petronell in Austria.

Reverse osmosis plant in Baden-Baden / Germany Municipal water treatment, PFC Treatment Permeate capacity 600 m3/h Number of plants: 6

In 2019 Xtype membrane housings were chosen at Hashemite University. A facility for research and development inaugurated by King Abdullah II of Jordan.

Technology development center in South Korea

Samsung Engineering

Reverse osmosis pilot plant.

Ultra Pure Water

Xtype membrane housings obtained French ACS approbation for drinking water.

Knappe Composites SAS won French municipal projects requiring ACS certification.

© 2024 Knappe Composites SAS ; Knappe Composites – X-Type RO Membrane Housings. | Webdesign by ComUnique.fr